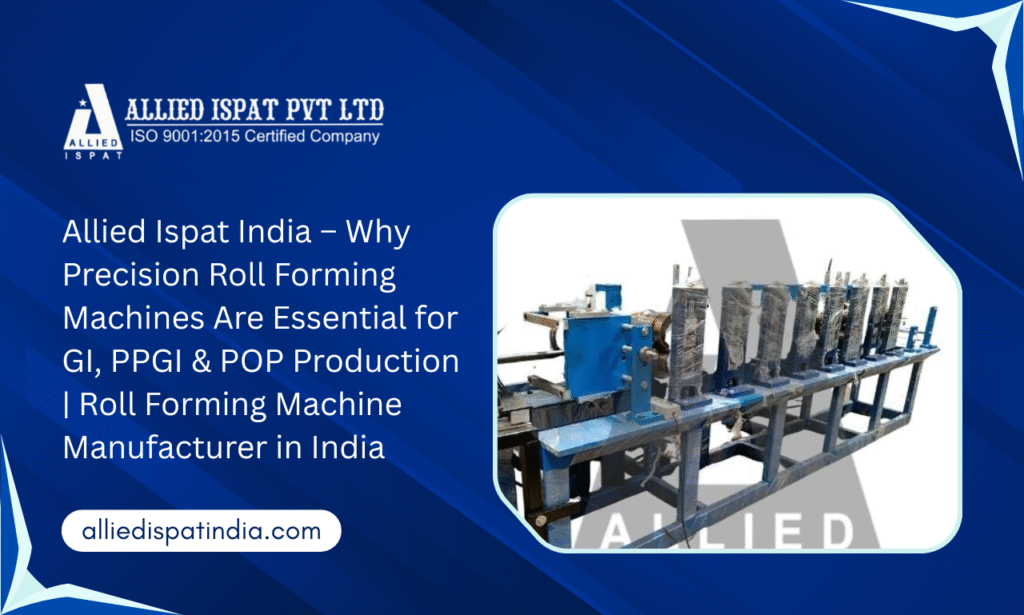

Introduction: Allied Ispat India Leads the Precision Revolution

Allied Ispat India, a trusted Roll Forming Machine Manufacturer in India, has been at the forefront of steel innovation for over five decades. As manufacturing demands evolve with speed, precision, and customization, roll forming machines have become the backbone of high-quality GI channels, PPGI sheets, and POP components.

From advanced shutter production lines to fully automated ceiling section equipment, Allied Ispat India empowers manufacturers to meet the market’s demands with consistency, speed, and quality assurance. Whether you’re producing in bulk or engineering bespoke projects, the choice between manual, semi-auto, and fully automatic roll forming machines directly impacts your operational efficiency, output, and product integrity.

In this blog, we explore the critical role of roll forming machines in modern sheet metal production and help you decide which machine type is best for your business.

1. The Role of Roll Forming in Modern GI, PPGI & POP Production

- What Is Roll Forming?

Roll forming is a continuous bending operation where long strips of metal typically coiled steel are passed through sets of rolls mounted on consecutive stands. Each set performs incremental parts of the bend, producing the desired cross section profile. - Why Precision Matters

In PPGI sheet forming and GI channel forming, even a 1mm deviation can cause failures in structure or poor aesthetics. Precision ensures every unit is within spec, enhancing durability and performance. - Products Made via Roll Forming

PPGI roofing sheets, GI channels, shutter guides, POP frame sections, metal angles, studs, and cable trays are some key products made using this process. - Consistency in Output

Roll forming is unmatched when it comes to repeatable, high-speed, high-volume production. B2B clients depend on this reliability for large scale operations. - Sustainability Edge

By using raw materials more efficiently and minimizing waste, roll forming Machine offers eco-friendly benefits. The closed-loop process reduces scrap, energy use, and downtime.

2. Types of Roll Forming Machines: Manual vs Semi Auto vs Fully Automatic

- Manual Roll Forming Machines

- Ideal for startups or small-batch production.

- Inexpensive but dependent on manual feeding and cutting.

- Requires skilled labor and may result in slower output.

- Semi-Automatic Machines

- Balances automation with cost effectiveness.

- Machines handle the rolling and cutting, while feeding may be manual.

- Great for mid-sized manufacturers looking for output and control.

- Fully Automatic Machines

- Complete automation from decoiling to final cutting.

- PLC control systems ensure precise operation.

- Ideal for high volume production with minimal labor and consistent quality.

- Which One Should You Choose?

Your decision should be based on production volume, labor availability, project size, and budget. Fully automatic systems offer long-term ROI and lower operational costs.

3. Allied Ispat India: Pioneering Roll Forming Machine Manufacturer in India

- Decades of Experience

Allied Ispat India is part of the Malik Group and has over 50 years of experience in metal solutions. - ISO 9001:2015 Certified

We meet international quality management standards, ensuring excellence in design and delivery. - State-of-the-Art Facilities

Our manufacturing facility in MIDC Taloja is equipped with cutting-edge CNC machines and automated testing systems. - Skilled Technical Team

From concept to commissioning, our team ensures seamless design, build, and integration support. - Domestic and International Reach

We serve clients across India, the Middle East, Africa, and South Asia, supplying customized forming machinery.

4. Key Benefits of Allied’s Precision Roll Forming Machines

- Dimensional Accuracy

Our machines produce accurate profiles every time, ensuring tight tolerances and perfect finishes. - Fast Line Speeds

Production lines can run at up to 60 meters per minute, increasing daily output. - High Production Uptime

Engineered for continuous operations with minimal maintenance. - Long Lasting Rollers

Alloy steel rollers with hard chrome plating provide durability and wear resistance. - Versatile Applications

Suitable for PPGI sheet forming, GI channel forming machine needs, POP ceiling frames, and more.

5. Applications of GI Channel & PPGI Sheet Forming Machines

- POP Ceiling Frames

Precise U and C channels for suspended false ceilings, a favorite among interior contractors. - Rolling Shutters

Forming shutter slats, side channels, bottom rails with clean interlocking. - Roofing & Cladding

PPGI trapezoidal, tile, and corrugated profiles for industrial and commercial roofing. - Drywall Systems

Making steel studs and tracks used in office partitions and modular cabins. - Automotive and HVAC

Producing brackets, frames, and ducts for various industrial applications.

6. Choosing the Right Machine: Factors to Consider

- Your Product Portfolio

More SKUs or complex profiles? Opt for programmable, automatic systems. - Daily Output Requirements

Higher volumes demand automation to minimize manual errors and fatigue. - Raw Material Type & Thickness

Machines must accommodate GI, PPGI, or CR coils of varying gauges. - Floor Space Availability

Compact designs can help save space while still delivering high performance. - Expansion Plans

Choose a machine that can scale with your future capacity needs.

7. What Makes Allied Ispat India Machines Stand Out

- Customization

Every machine is engineered to suit your production line’s requirements. - After-Sales Support

On-site training, spare parts, troubleshooting, and upgrades available pan-India. - Multi-Profile Compatibility

Machines can switch between profiles with minimal tool changes. - Integration-Ready Design

Works seamlessly with punching, shearing, and stacking units. - Affordable Automation

We bring advanced automation at competitive prices for Indian manufacturers.

8. How to Get Started with Allied Ispat India

- Site Assessment

We visit your factory to assess layout, power, and production flow. - Custom Proposal

We provide tailored machine specifications, ROI projections, and pricing. - Manufacturing & Testing

Machines are built, tested, and quality-checked at our MIDC Taloja facility. - Installation & Commissioning

Full on-site setup with operator training and performance calibration. - Post-Sale Service

Dedicated support team ensures high uptime and preventive maintenance.

Conclusion: Invest in Precision, Invest in Allied Ispat India

In a competitive global market, precision, consistency, and speed are non-negotiable. Whether you’re manufacturing for local infrastructure, export-grade roofing sheets, or industrial shutter systems, your production line must be as efficient as your ambition.

As a top-tier Roll Forming Machine Manufacturer in India, Allied Ispat India delivers not just machines but manufacturing excellence. With advanced options for PPGI sheet forming, GI channel forming, and POP section production, our systems help you scale faster, reduce costs, and maintain quality standards across every unit.

Partner with Allied Ispat India for your next roll forming machine requirement and see how innovation transforms output.

Contact Allied Ispat India Today

Let’s build your future ready production line.

Allied Ispat Mumbai Central Office

69, Chotta Sonapur, Maulana Shaukat Ali Road, Mumbai – 400008

Phone: 098211 77009

Manufacturing Facility

Plot No. C-17/9, MIDC Taloja, Behind Bank of Baroda, Dist. Raigad – 410208

Phone: 8779051606

Get Directions: https://maps.app.goo.gl/iNK8ZZvn85h5absd6

Website: https://alliedispatindia.com