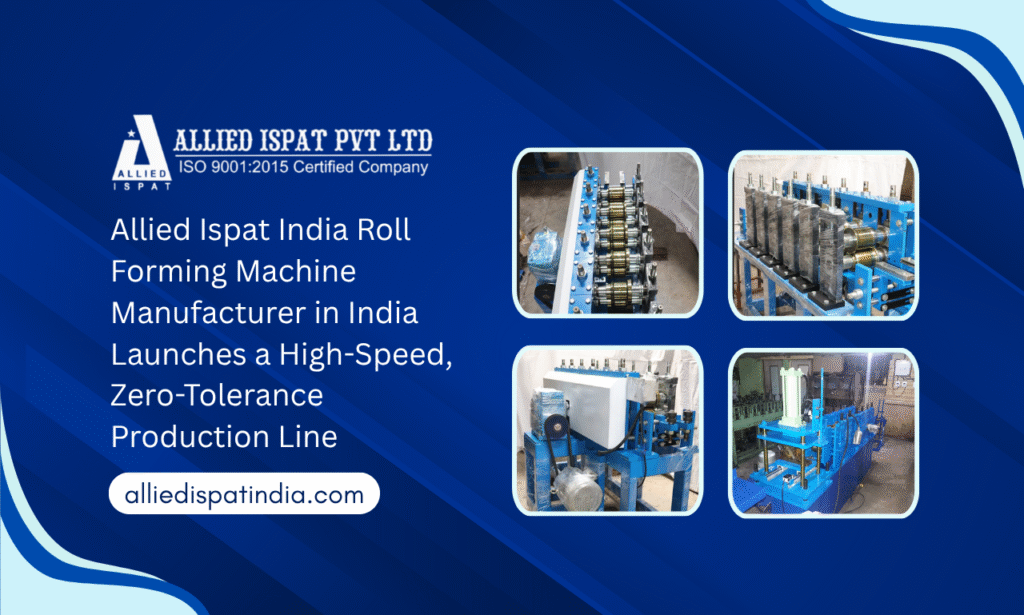

Allied Ispat India – Roll Forming Machine Manufacturer in India Launches a High-Speed, Zero-Tolerance Production Line

Allied Ispat India, a leading Roll Forming Machine Manufacturer in India, has taken a significant leap forward with the introduction of its high-speed, zero-tolerance roll forming machine line. As a recognized Roll Forming Machine Manufacturer in Mumbai and a trusted Roll Forming Machine Supplier in India, the company’s latest innovation is engineered to meet the growing demand for precision, consistency, and scalable production in modern manufacturing environments.

Backed by decades of expertise under the Malik Group of Companies, Allied Ispat India continues to lead the Indian sheet metal machinery market with cutting-edge forming solutions. The company operates from its Mumbai Central office and a fully-equipped manufacturing facility in MIDC Taloja, offering comprehensive services across the country and beyond.

Legacy of Innovation and Engineering Excellence

With over 50 years of experience, Allied Ispat India has built a legacy rooted in innovation, reliability, and performance. From early manual systems to today’s automated production lines, the company has consistently delivered solutions that enhance operational efficiency across multiple industries.

Each roll forming machine is meticulously designed to serve evolving needs in infrastructure, real estate, industrial fabrication, and renewable energy sectors. The company’s success as a Roll Forming Machine Manufacturer in Mumbai is driven by its ability to combine traditional expertise with modern engineering practices. As the demand for customized metal forming grows, Allied has continually adapted by integrating cold roll forming technology and precision CNC roll systems to maintain tight tolerances.

Features of the New Roll Forming Machine Line

The newly launched roll forming line is designed to deliver zero-defect output even under high-speed manufacturing conditions. It supports automated coil feeding, advanced servo motors, and PLC-controlled operations for uninterrupted performance. Designed to match international benchmarks, this equipment is ideal for clients with large-scale production requirements.

Key features include:

- High-speed production capability of up to 60 meters per minute

- CNC-controlled roll positioning for dimensional accuracy

- Rapid tooling changeover with minimal downtime

- Precision forming for a wide range of profiles including GI channels, ceiling sections, and solar structures

- Integrated error detection systems to ensure product consistency

- Compatibility with stainless steel, aluminum, and galvanized coils

- IoT-based diagnostics and real-time production data tracking

This advanced equipment is a perfect fit for manufacturers aiming for volume production without compromising quality or efficiency. The machine design emphasizes low maintenance and operator-friendly interfaces, ensuring optimal performance across shift operations.

Scalability for Mass Production

The new roll forming line is particularly suited for industries requiring large-scale, uninterrupted output. Whether producing profiles for rolling shutters, door frames, or solar mounting structures, the machine ensures uniformity and high throughput. Allied’s machines serve as the foundation for automated production systems that can grow with your business.

Designed for continuous 24×7 operation, it is ideal for manufacturers supplying infrastructure projects such as airports, metro stations, warehouses, and commercial complexes. Automated coil processing and profile accuracy further enhance its utility in mass production environments. With the ability to link multiple forming units into a single automated production line, businesses can scale operations while keeping labor costs low.

Custom-Engineered to Fit Specific Applications

Allied Ispat India provides extensive customization options, ensuring that each machine aligns with the client’s production objectives. From sheet thickness and material type to specific geometry and tooling, every aspect of the machine can be tailored to meet your operational needs.

Custom configurations include:

- Roofing sheet roll forming lines with various pitch profiles

- False ceiling channel forming machines for modular construction

- Solar panel structure roll forming lines compatible with varied mounting systems

- Partition profile machines for lightweight infrastructure

- Cable tray roll forming machines for electrical infrastructure projects

- Z purlin roll forming machines with adjustable flange sizes

- Door frame roll forming lines with punch and cut-to-length automation

All custom machines undergo digital prototyping, simulations, and quality checks before dispatch, ensuring compatibility and ease of integration. Allied’s in-house R&D team works closely with the client’s engineers to co-create forming solutions that are practical, scalable, and profitable.

Applications Across Key Industry Sectors

The new roll forming line addresses the needs of multiple high-demand sectors, including:

- Construction: GI channel and ceiling section forming machines for residential and commercial buildings

- Renewable Energy: Roll forming machines for solar panel structures and mounting systems

- Electrical Infrastructure: Cable tray and partition profile systems

- Industrial Fabrication: Door frames, shutter guides, and structural Z purlins

- Logistics and Warehousing: Shutter profile systems for industrial doors and security enclosures

- Retail and Commercial Interiors: False ceiling and dry partition channel machines for modular office installations

Each solution is engineered to meet industry-specific standards for strength, durability, and efficiency. This makes Allied Ispat a preferred partner for contractors, developers, OEMs, and turnkey project providers across India.

Smart Manufacturing and Industry 4.0 Integration

Allied’s roll forming machines are Industry 4.0-ready, enabling smart manufacturing through integrated IoT sensors, real-time data tracking, and predictive maintenance capabilities. These systems allow manufacturers to streamline operations, reduce downtime, and improve overall equipment effectiveness.

Advanced features include:

- CNC automation for quick profile programming

- PLC-controlled systems for precise line operations

- IoT connectivity for remote monitoring and diagnostics

- Cloud-compatible analytics for performance optimization

- Predictive alerts for wear-and-tear parts

- Machine learning integration for defect prediction

This intelligent architecture ensures long-term reliability and future-proofing of the production line. Clients benefit from centralized control dashboards, digital production records, and integration with ERP systems for seamless factory management.

Commitment to Quality, Compliance, and Operational Safety

Each roll forming machine undergoes rigorous quality assurance procedures, including:

- Structural and dimensional verification

- Load capacity and tolerance testing

- CE and ISO 9001:2015 compliance

- Operator safety systems and documentation

- Lifecycle testing for durability and performance

- Electrical compliance and EMI protection

Allied Ispat India also provides site-specific risk assessments, machine certification documents, and post-installation safety training. Clients receive complete operation manuals and access to the company’s technical support team for troubleshooting and upgrades.

Why Manufacturers Choose Allied Ispat India

As a Roll Forming Machine Supplier in India with a strong B2B focus, Allied Ispat India has earned the trust of contractors, OEMs, infrastructure developers, and industrial manufacturers. Its reputation is built on client-centric engineering, transparent communication, and unmatched after-sales support.

Clients choose Allied because of:

- Customized solutions tailored to production goals

- Proven track record across sectors and geographies

- Nationwide support and fast-response service teams

- Transparent pricing and lifecycle value

- Consistent quality backed by ISO-certified processes

- Pan-India logistics and installation capability

- Access to spare parts, training modules, and warranty services

By aligning technology with production needs, Allied delivers measurable outcomes in terms of efficiency, reliability, and return on investment. Its roll forming systems are currently running in factories across Mumbai, Pune, Hyderabad, Delhi, and Tier-II industrial clusters in India.

Conclusion

Allied Ispat India’s new roll forming machine line represents a strategic advancement in precision sheet metal manufacturing. As a Roll Forming Machine Manufacturer in India and a prominent Roll Forming Machine Manufacturer in Mumbai, Allied is setting new benchmarks for speed, accuracy, and smart integration.

For businesses seeking a trusted Roll Forming Machine Supplier in India capable of delivering tailored, future-ready solutions, Allied Ispat India remains the partner of choice.

Contact Details:

Mumbai Central Office:

69, Chotta Sonapur, Maulana Shaukat Ali Road, Mumbai – 400008

Phone: +91 98211 77009

Manufacturing Works:

Plot No. C-17/9, MIDC Taloja, Behind Bank of Baroda, Dist. Raigad 410208

Phone: +91 87790 51606

Website: https://alliedispatindia.com

Google Maps: https://maps.app.goo.gl/iNK8ZZvn85h5absd6