Introduction

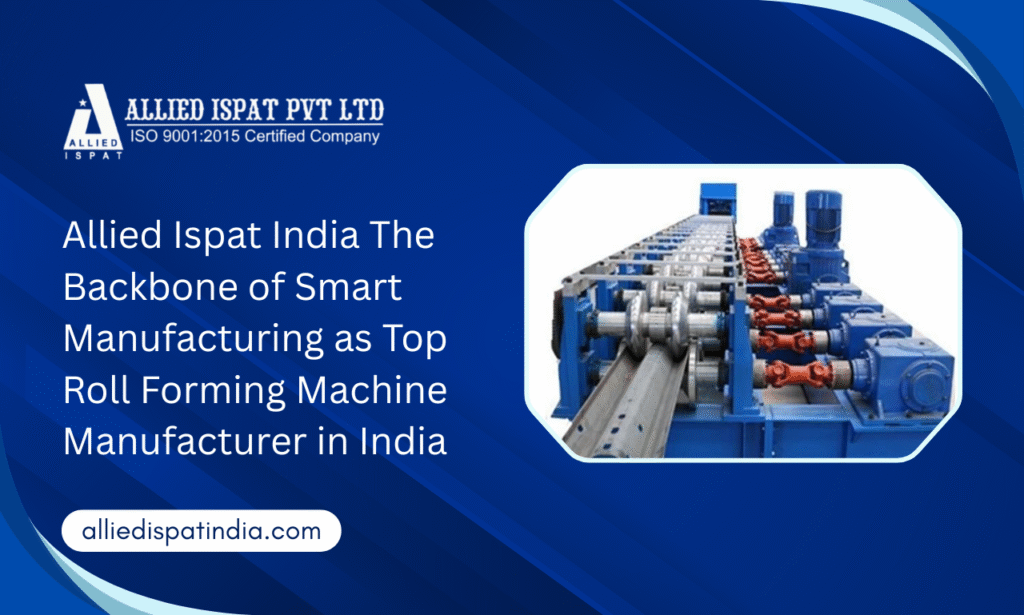

Allied Ispat India, a reputed Roll Forming Machine Manufacturer in India, is setting new standards in smart manufacturing for the infrastructure and industrial sectors. As India’s demand for precision engineered metal components continues to grow, Allied Ispat delivers high-performance roll forming machines tailored to meet the evolving needs of B2B manufacturers across the country. With over five decades of legacy under the Malik Group of Companies, the company blends traditional expertise with future-ready technology, creating a new era in metal forming solutions.

1. Smart Manufacturing in India: The New Industrial Revolution

- Rise of Automation: Indian factories are moving towards automation, and roll forming is central to this transformation. Allied Ispat offers machines equipped with digital PLC control panels, auto-cutting systems, and minimal manual intervention.

- Precision at Scale: From rolling shutters to structural channels, Allied Ispat machines ensure precision profiles with reduced waste.

- Affordable Technology: Designed with the Indian manufacturing ecosystem in mind, our machines are cost-effective, energy-efficient, and low-maintenance.

- Aligned with “Make in India”: Our roll forming machines help local manufacturers reduce imports and strengthen India’s industrial self-reliance.

- Wide Applications: Roofing, partition systems, shutter manufacturing, and automotive sheet metal our roll formers are powering them all.

2. Allied Ispat: Leading Roll Forming Machine Manufacturer in India

- Established Legacy: A part of the Malik Group, Allied Ispat brings 50+ years of industry insight into roll forming technology.

- Pan-India Reach: From our Taloja MIDC factory, we cater to clients in Navi Mumbai, Pune, Hyderabad, Gujarat, and beyond.

- Custom Machine Solutions: We don’t just sell machines—we co-create solutions based on your product specs, volume needs, and factory layout.

- ISO 9001:2015 Certified: Each machine is designed and tested as per international standards to ensure long-term durability and operational excellence.

- Trusted B2B Partner: Builders, OEMs, exporters, and fabricators across India rely on Allied Ispat’s technology and after-sales support.

3. Roll Forming Technology: How It Works and Why It Matters

- Continuous Cold Bending: Roll forming shapes long steel strips into complex profiles without heat, ensuring dimensional stability.

- Energy Efficient: Cold-forming saves energy and reduces deformation risk, making it ideal for industrial-scale production.

- Tooling Versatility: Allied Ispat machines allow quick die changes for different products—saving time and boosting productivity.

- Minimal Scrap Loss: Precision-driven forming tools reduce material waste, saving raw material costs in large batches.

- Digital Programming: Automated batch control, programmable length settings, and touchscreen interfaces enhance user control.

4. Why B2B Manufacturers Prefer Allied Ispat Roll Forming Machines

- Customizable Machinery: Get machines suited to your metal thickness, profile shape, and production targets.

- Durable Construction: Made from high-grade materials, our roll formers are built to endure high-volume operations.

- Compact Footprint: Space-saving designs help maximize productivity even in small to medium-sized factories.

- Ease of Use: With PLC panels and auto-lubrication systems, operators require minimal training.

- Responsive Support: Installation, training, spare parts, and servicing—all provided directly by our technical team.

5. Product Portfolio: Allied Ispat Roll Forming Machines

- Rolling Shutter Profile Machines: Machines that produce shutter slats, guide channels, side plates, and spring boxes.

- POP & Ceiling Section Machines: Fabricate intermediate, perimeter, and wall angle channels with sharp precision.

- C & Z Purlin Roll Formers: Heavy-duty machines for structural and roofing applications, built for large-scale projects.

- Roofing Sheet Profile Machines: Create trapezoidal, corrugated, and other profiles for industrial sheds and warehouses.

- Door Frame Forming Machines: Ideal for architectural and modular construction applications.

6. Key Innovations in Allied Ispat Machines

- Hydraulic Cutting Systems: Achieve cleaner cuts and longer blade life with advanced hydraulic cutting tech.

- Servo Motor Drives: Ensure faster, smoother, and more accurate material feeding.

- Quick Die Change: Reduce production downtime with modular tooling systems.

- Remote Troubleshooting: Our newer models offer IoT-enabled features for remote diagnostics.

- Batch Management Software: Control your production data through touchscreen HMIs with real-time tracking.

7. After-Sales Support & Client Services

- Free Installation & Setup: Our team handles delivery, placement, wiring, and trial runs at your site.

- Hands-On Operator Training: We educate your team on machine usage, safety protocols, and daily maintenance.

- Annual Maintenance Plans: Get priority service, preventive checkups, and discounted spare parts.

- Spare Parts Inventory: All critical spares are stocked at our warehouse for fast delivery.

- Customer Helpline: Phone and video call support available for instant troubleshooting and service booking.

8. What’s Next for Roll Forming in India?

- Green Engineering: Allied Ispat is working on machines that reduce energy usage and material scrap to meet sustainability goals.

- Global Exports: We’re engineering machines that comply with CE standards and dual voltage setups for international markets.

- Modular Automation: Future machines will include AI-driven sensors for predictive maintenance.

- Smart Coil Handling: Integration with decoilers, stackers, and conveyors for hands-free operations.

- Collaborative Innovation: We partner with contractors, OEMs, and product developers to co-create next-gen forming systems.

Conclusion: Let’s Shape the Future Together

At Allied Ispat India, we believe that manufacturing excellence comes from more than just machines it comes from passion, partnerships, and performance. As a leading Roll Forming Machine Manufacturer in India, our mission is to empower every factory, fabricator, and industrial builder with technology that delivers consistency, efficiency, and long-term ROI.

If you’re looking to automate your metal forming process with a trusted, proven solution, we’re just a call away.

Allied Ispat India – Mumbai Central Office

Address: 69, Chotta Sonapur, Maulana Shaukat Ali Road, Mumbai – 400008

Phone: +91 9821177009

Works Address – Taloja MIDC

Plot no. C-17/9, MIDC Taloja, Behind Bank of Baroda, Dist. Raigad 410208

Phone: +91 8779051606

Google Maps: https://maps.app.goo.gl/gyEqxBGcw9jLsYm26

Website: www.alliedispatindia.com