Introduction

In 2026, the Indian construction, infrastructure, and manufacturing ecosystem is more quality-driven than ever before. EPC contractors, roll forming machine operators, OEMs, fabricators, and industrial developers are no longer selecting steel purely on price. Instead, they are prioritizing performance reliability, finish consistency, corrosion resistance, lifecycle cost, and supply assurance. At the heart of these decisions lies one critical material choice: trading coils.

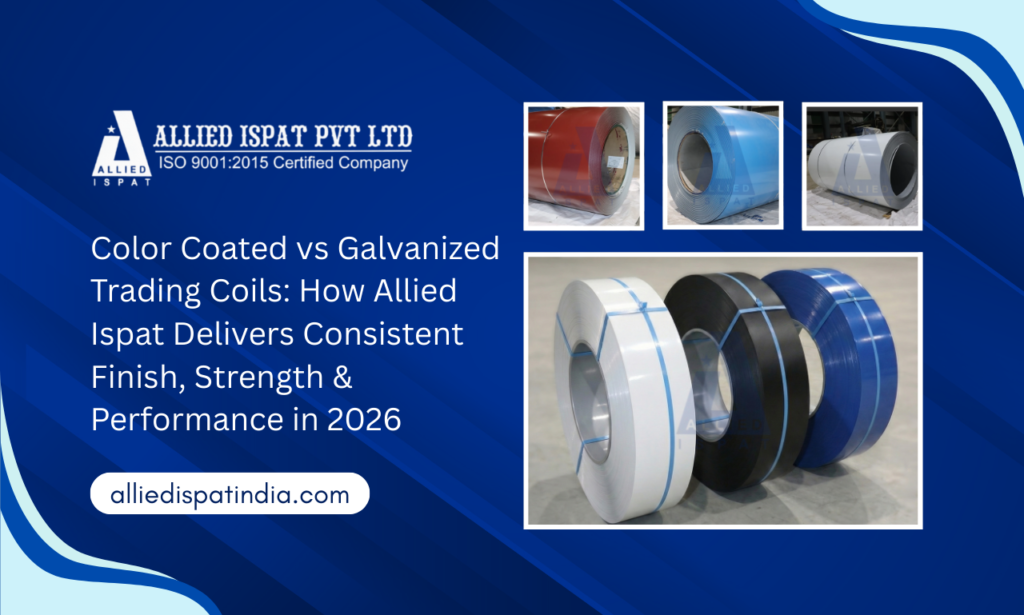

Trading coils form the backbone of modern steel-based manufacturing. From industrial roofing and wall cladding to rolling shutter systems, pre-engineered buildings, and structural fabrication, the right coil specification directly affects output quality, installation efficiency, and long-term durability. Choosing between Color Coated Trading Coils and Galvanized Trading Coils is therefore not a minor technical decision—it is a strategic one.

Allied Ispat Pvt. Ltd., a trusted Trading Coil Manufacturer in India and an established Trading Coil Manufacturer in Mumbai, has consistently supported B2B buyers with ISO-compliant steel processing, controlled coating quality, and dependable nationwide supply. This in-depth guide explains the real-world differences between color coated and galvanized trading coils—and how Allied Ispat Pvt. Ltd. ensures consistent finish, strength, and performance across both categories.

What Are Trading Coils and Why Do They Matter in Modern Manufacturing?

Trading coils are pre-processed steel coils supplied in specific thicknesses, widths, and coating formats, ready for direct use in downstream manufacturing or construction applications. Unlike raw steel inputs, trading coils are engineered for machine compatibility, predictable forming behavior, and consistent output quality.

In industrial practice, trading coils are used extensively for:

- Roll forming machines producing roofing sheets, wall panels, purlins, and profiles

- Rolling shutter slats, guides, and structural components

- Roofing and cladding systems for industrial sheds and commercial buildings

- Structural fabrication for warehouses, logistics parks, and factories

- Appliance panels, enclosures, and industrial housings

For OEMs and contractors, working with a dependable Trading Coil Manufacturer in India minimizes production disruptions, material rejections, and installation delays. As a Steel Coil Supplier in India with deep industry understanding, Allied Ispat Pvt. Ltd. supplies coils that integrate seamlessly into production lines while meeting structural and aesthetic expectations.

Understanding Color Coated Trading Coils

Color coated trading coils are steel coils that undergo a multi-stage coating and painting process to enhance corrosion resistance while delivering superior surface aesthetics. These coils are widely used where visual appeal, long-term durability, and environmental resistance are equally important.

Coating Structure and Layer Composition

Color coated coils typically consist of:

- High-quality steel substrate

- Metallic coating (GI or GL) for primary corrosion protection

- Primer layer to enhance paint adhesion

- Top coat providing color, gloss, and surface durability

This layered system ensures that Color Coated Trading Coils maintain both structural integrity and surface performance over extended service life.

Finish Consistency and Visual Uniformity

In large commercial or industrial projects, maintaining uniform color shade and gloss across thousands of square meters is critical. Variations in finish can compromise architectural aesthetics and brand perception. As a quality-focused Color Coated Coil Manufacturer–aligned supplier, Allied Ispat Pvt. Ltd. emphasizes batch-to-batch color consistency, ensuring visual uniformity across multiple deliveries.

Corrosion Resistance in Indian Conditions

India’s diverse climate ranging from coastal humidity to industrial pollution demands advanced corrosion protection. Color coated coils provide enhanced resistance against moisture, UV radiation, and chemical exposure, making them suitable for both urban and industrial environments.

Performance Advantages of Color Coated Trading Coils

- Reduced repainting and maintenance costs

- Extended service life in aggressive environments

- Enhanced aesthetic appeal for visible applications

- Reliable performance in roofing and cladding systems

Understanding Galvanized Trading Coils

Galvanized trading coils are steel coils coated with zinc to protect against corrosion while retaining high structural strength. These coils are widely used in load-bearing and functional applications where durability and cost efficiency are primary considerations.

Zinc Coating Process Explained

Through hot-dip galvanization, steel coils are immersed in molten zinc. This creates a metallurgical bond that protects the steel substrate. Even if the surface is scratched, zinc continues to offer sacrificial protection, preventing rust formation.

Structural Strength and Mechanical Reliability

Galvanized Trading Coils maintain the inherent strength of steel, making them suitable for heavy-duty applications. Their mechanical stability ensures predictable behavior during forming, fabrication, and installation.

Weather Resistance Across Applications

Galvanized coils perform exceptionally well in outdoor and semi-exposed environments. For industrial sheds, warehouses, and rolling shutter components, they offer long-term reliability with minimal maintenance.

Cost-Efficiency for Large-Scale Projects

For projects with large steel consumption volumes, galvanized coils provide an optimal balance between performance and cost. This makes them a preferred choice for contractors managing tight budgets without compromising structural safety.

Color Coated vs Galvanized Trading Coils: A Practical Comparison

Understanding the differences between color coated and galvanized coils helps buyers make informed, application-specific decisions.

Finish and Appearance

Color coated coils offer superior aesthetics with consistent color and gloss. Galvanized coils have a metallic finish that prioritizes functionality over appearance.

Strength and Durability

Both coil types provide excellent strength. However, galvanized coils are often preferred for structural and concealed components, while color coated coils are chosen for visible surfaces.

Corrosion Protection

Color coated coils combine metallic and paint protection, offering enhanced corrosion resistance in aggressive environments. Galvanized coils rely on zinc protection, which remains highly effective for structural applications.

Application Suitability

- Color coated coils: roofing, cladding, architectural panels

- Galvanized coils: frames, supports, rolling shutters, fabrication

Maintenance and Lifecycle Cost

Color coated coils reduce long-term maintenance costs, while galvanized coils offer a cost-effective solution for strength-driven projects.

How Allied Ispat Pvt. Ltd. Ensures Consistent Finish and Strength

Consistency is the most critical factor in B2B steel procurement. As a Trading Coil Manufacturer in Mumbai serving customers across India, Allied Ispat Pvt. Ltd. follows a disciplined, quality-first approach.

Controlled Raw Material Sourcing

Steel substrates are sourced from reliable mills, ensuring consistent chemical composition, mechanical properties, and coating compatibility.

Quality-Controlled Coating Processes

Strict monitoring of coating thickness, paint adhesion, and curing parameters ensures that every coil meets predefined quality benchmarks.

Thickness Uniformity and Dimensional Accuracy

Custom slit and wide-width coils are supplied with tight tolerances, enabling seamless integration into roll forming machines and fabrication lines.

Batch-to-Batch Consistency

Uniformity in color shade, zinc coating mass, and mechanical performance ensures continuity across repeat orders—critical for large infrastructure projects.

ISO-Compliant Supply Chain Practices

ISO-aligned systems ensure traceability, documentation, and quality assurance, reinforcing Allied Ispat Pvt. Ltd.’s credibility as a Trading Coil Manufacturer in India.

Which Trading Coil Is Right for Your Project?

Selecting the right trading coil depends on application requirements, environmental exposure, and performance expectations.

Industrial Sheds and Warehouses

Galvanized trading coils are ideal for structural members due to their strength and cost efficiency.

Commercial Buildings

Color coated trading coils are preferred for roofing and cladding where appearance and corrosion resistance matter.

Roofing and Wall Cladding Systems

Color coated coils deliver long-term finish stability and reduced maintenance.

Roll Forming Machines

Both coil types are suitable when specifications match machine requirements. Allied Ispat Pvt. Ltd. provides technical guidance to ensure compatibility.

Why Choose Allied Ispat Pvt. Ltd. as Your Trading Coil Partner?

In a competitive steel market, Allied Ispat Pvt. Ltd. differentiates itself through reliability, technical expertise, and customer-centric supply.

- Recognized Trading Coil Manufacturer in India with pan-India reach

- Established Trading Coil Manufacturer in Mumbai supporting OEMs and contractors

- Comprehensive range of color coated and galvanized trading coils

- Custom widths, thicknesses, and slit formats

- Strong technical support and application guidance

This approach positions Allied Ispat Pvt. Ltd. as a long-term partner rather than just a supplier.

FAQs:

What is the primary difference between color coated and galvanized trading coils?

Color coated coils include paint layers for enhanced aesthetics and corrosion resistance, while galvanized coils rely on zinc coating for structural protection and durability.

Which trading coil is better for roofing applications?

Color coated trading coils are preferred for roofing due to their weather resistance, color stability, and reduced maintenance requirements.

Are galvanized trading coils suitable for roll forming machines?

Yes, galvanized coils are widely used in roll forming due to their consistent mechanical properties and durability.

How does Allied Ispat Pvt. Ltd. maintain quality consistency?

Through controlled sourcing, quality checks, and ISO-aligned processes, Allied Ispat Pvt. Ltd. ensures consistent finish and performance.

Can customized coil sizes be supplied?

Yes, custom slit and wide-width coils are supplied to match specific machinery and application requirements.

Which industries commonly use color coated trading coils?

Construction, roofing, cladding, appliance manufacturing, and pre-engineered building sectors commonly use color coated coils.

Conclusion: Build with Confidence Using the Right Trading Coil

As infrastructure and manufacturing standards evolve in 2026, the importance of selecting the right trading coil cannot be overstated. Whether your project demands architectural aesthetics or structural strength, choosing the correct coil type directly impacts performance, durability, and lifecycle cost.

By combining ISO-compliant practices, customization capabilities, and dependable nationwide supply, Allied Ispat Pvt. Ltd. continues to strengthen its position as a trusted Trading Coil Manufacturer in India and a reliable Trading Coil Manufacturer in Mumbai.

Contact Allied Ispat India – Let’s Discuss Your Project Requirements

Head Office:

Allied Ispat Pvt. Ltd.

69, Chotta Sonapur, Maulana Shaukat Ali Road,

Mumbai – 400008

Phone: +91 98211 77009

Manufacturing Works:

Plot No. C-17/9, MIDC Taloja,

Behind Bank of Baroda, Dist. Raigad – 410208

Phone: +91 87790 51606

Email: info@alliedispatindia.com | sales@alliedispatindia.com

Website: www.alliedispatindia.com

Get Directions: https://maps.app.goo.gl/gyEqxBGcw9jLsYm26

Reach out today for bulk inquiries, technical consultations, or customized trading coil solutions engineered for performance and delivered with precision.