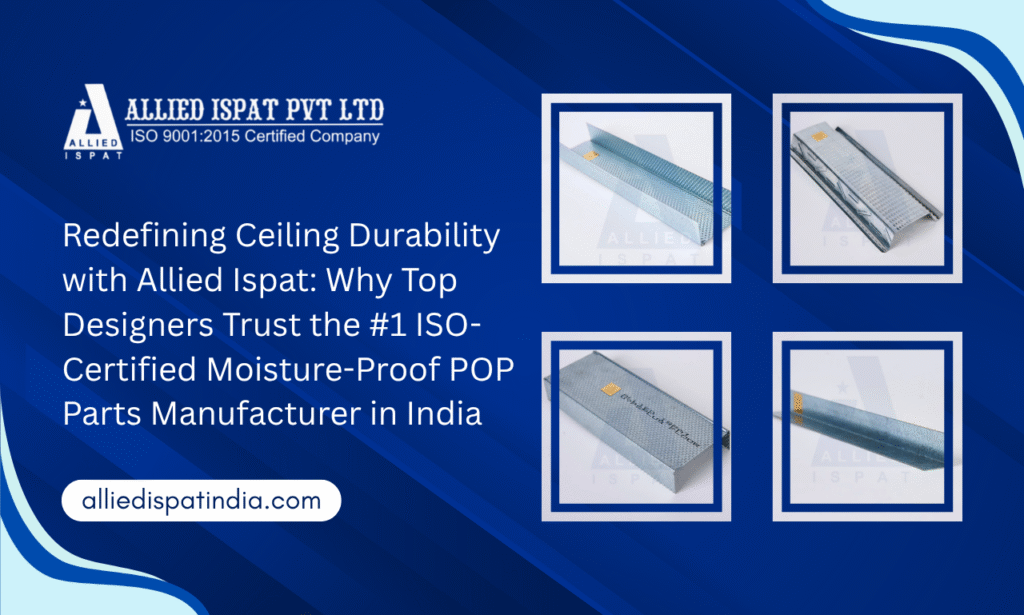

Allied Ispat India – Why Top Interior Designers Choose Our ISO 9001 Certified Moisture-Proof POP Parts in India

Allied Ispat India, one of the most trusted names in India’s steel and construction materials industry, has become a preferred partner for interior designers, contractors, and architects across the nation. As an ISO 9001:2015 certified POP parts manufacturer in India, the company delivers products that go beyond structural integrity they enhance design efficiency, long-term durability, and aesthetic appeal.

In an era where design meets engineering, Allied Ispat India has redefined the way POP frames are manufactured. Whether it’s a luxury apartment in Mumbai, a hospital in Kerala, or a corporate office in Bengaluru, every project demands reliable ceiling and partition systems that can perform under challenging conditions like humidity, heat, and load pressure. And this is exactly where Allied Ispat’s moisture-proof POP parts make the difference.

Rising Demand for Quality POP Parts in Modern Interiors

As interior spaces become more functional, designers are no longer focusing solely on aesthetics. Today, the success of a modern ceiling system depends on the strength, finish, and resistance of its framework. POP ceilings are integral to modern architecture providing both beauty and function by hiding electrical wiring, ductwork, and lighting elements.

However, traditional POP sections often fail when exposed to moisture or heavy loads. This has pushed architects and B2B contractors to seek industrial metal solutions that guarantee stability and longevity. Allied Ispat India, with its range of moisture-proof, high-performance GI-based POP sections, has emerged as a pioneer in this transformation.

Allied Ispat’s POP Product Range: GypsPlus Premium & GypsPlus Xpert-Plus

GypsPlus Premium – Engineered Strength for Industrial & Commercial Projects

GypsPlus Premium is built for performance, crafted from prime-grade galvanized steel (0.5–0.7mm) to handle demanding environments such as factories, hospitals, airports, and coastal projects.

These heavy-duty frames feature a knurled surface for better grip, work-hardened steel for stability, and a load capacity of up to 50kg/m², making them ideal for installations that need to last for years without sagging or corrosion.

Core Highlights:

- Material: Prime-grade GI steel with enhanced corrosion resistance.

- Technology: Cold-rolled pre-forming for dimensional accuracy.

- Durability: Sag-proof, rust-proof, and moisture-resistant.

- Applications: Industrial ceilings, humid zones, hospitals, and coastal constructions.

GypsPlus Premium isn’t just a ceiling section it’s a long-term structural investment that supports heavy loads and promises absolute reliability.

GypsPlus Xpert-Plus – Lightweight Precision for Design-Friendly Interiors

For interior designers who prioritize visual appeal along with easy installation, GypsPlus Xpert-Plus is the ultimate choice. Designed for luxury homes, offices, showrooms, and creative ceiling designs, this range balances aesthetics with precision.

Crafted with 0.40–0.45mm prime-grade GI steel, each piece offers clean folded edges for safety and customizable lengths (8ft/12ft) to reduce wastage and speed up installations.

Core Highlights:

- Design Compatibility: Ideal for decorative, layered, or 3D ceilings.

- Safety Assurance: Folded edges minimize handling risks.

- Ease of Use: Lightweight and easy to cut or install.

- Custom Options: Tailored lengths for unique project needs.

Both product lines GypsPlus Premium and GypsPlus Xpert-Plus reflect Allied Ispat India’s expertise as a top POP parts supplier in India, combining strength, safety, and style for a variety of B2B applications.

Precision Manufacturing: Where Quality Meets Consistency

What truly separates Allied Ispat India from other manufacturers is its precision-driven manufacturing process. With advanced roll forming technology, every POP section undergoes multiple stages of testing from raw material analysis to final inspection.

Each product is ISO 9001:2015 certified, ensuring that it meets international standards of quality and reliability. Using automated roll forming machines, Allied Ispat achieves perfect alignment and uniform thickness vital for large-scale projects where consistency determines performance.

For interior contractors managing multiple sites, this reliability translates to reduced installation time, fewer reworks, and a superior finish.

Why Top Interior Designers and Contractors Prefer Allied Ispat India

1. ISO-Certified Quality Control

Every POP frame manufactured by Allied Ispat India adheres to ISO 9001:2015 quality standards, ensuring corrosion resistance, structural strength, and visual precision. This level of standardization guarantees that every batch meets the same benchmark whether for a local builder or a national infrastructure project.

2. Tailored Solutions for Every Project

From modern corporate spaces to artistic residential interiors, Allied Ispat provides customization options in lengths, coatings, and specifications. This adaptability makes it easy for architects and designers to align structural requirements with design intent.

Custom orders can include non-standard lengths, thickness variations, and finish customization based on humidity exposure or design complexity.

3. Trusted by Leading B2B Clients

With a legacy built on precision, Allied Ispat India has served industrial and commercial contractors, architects, and OEM partners across India. The brand’s ability to meet bulk orders, OEM manufacturing, and project-based demands positions it among the most reliable B2B manufacturing solutions providers in the country.

4. Nationwide Supply Chain & Export Capability

With a strong base in Mumbai Central and manufacturing facilities at MIDC Taloja (Raigad), Allied Ispat ensures quick and efficient delivery across India. Its logistics infrastructure also supports international shipments, making it a reliable export partner for clients seeking high-quality metal components abroad.

5. End-to-End B2B Support

From design consultation to material dispatch, Allied Ispat India offers complete support for B2B buyers, including OEM collaborations, private labeling, and technical documentation. Every partnership is guided by transparency, quality assurance, and timely execution.

Beyond POP Parts: Allied Ispat’s Comprehensive Metal Product Range

While POP parts remain a flagship product, Allied Ispat India operates as a multi-specialty steel manufacturer delivering integrated industrial solutions across multiple sectors.

Rolling Shutter Parts Manufacturing

Engineered for safety and durability, Allied’s rolling shutter components including shafts, slats, springs, and brackets are used by builders, fabricators, and automation brands nationwide.

Roll Forming Machine Solutions

As a roll forming machine manufacturer in India, Allied Ispat offers customized equipment designed for precision shaping of steel coils into POP channels, shutter strips, and other industrial profiles.

Trading Coil Supply & Distribution

The company also deals in galvanized and color-coated trading coils, catering to industries that demand anti-corrosive, aesthetic, and high-strength materials for cladding and roofing systems.

Each vertical strengthens Allied’s reputation as a comprehensive industrial metal solutions provider, serving both infrastructure and interior segments.

Applications: Where Allied Ispat POP Frames Shine

The versatility of Allied Ispat’s POP frames allows them to be used across diverse industries and spaces:

- Commercial Buildings: Offices, showrooms, malls, and hotels.

- Residential Projects: Luxury flats, villas, and smart homes.

- Healthcare Infrastructure: Hygienic, rust-proof ceilings for hospitals and labs.

- Factories & Warehouses: Heavy-duty load-bearing frames for industrial ceilings.

- Coastal Construction: Moisture-resistant and corrosion-proof for humid climates.

Every application benefits from Allied’s balance of strength and design making it the preferred POP parts manufacturer in India for top construction and design firms.

Commitment to Sustainability and Innovation

In today’s construction ecosystem, sustainability is as critical as performance. Allied Ispat India integrates eco-friendly practices throughout its production process from using recyclable materials to minimizing waste in manufacturing.

By optimizing its roll forming operations and adopting energy-efficient systems, the company ensures lower emissions and resource conservation. This focus aligns with global trends toward green construction and responsible industrial practices.

A Partner You Can Trust: Why Choose Allied Ispat India

When you choose Allied Ispat India, you’re partnering with a brand that delivers strength, trust, and consistency at every level of production and service.

Here’s what makes Allied Ispat India stand out:

- Decades of Industry Experience — Over 20 years of serving India’s growing infrastructure sector.

- ISO 9001:2015 Certified Manufacturing Guaranteed quality and uniformity.

- Bulk & OEM Supply — Seamless scalability for large projects and private label brands.

- Pan-India Logistics — Reliable and timely delivery from Mumbai to every corner of India.

- Product Diversity — From POP frames to trading coils, one-stop metal solutions under one brand.

- Customer-Centric Approach — Focused on building long-term B2B relationships with transparency and reliability.

Whether you’re a contractor, builder, or architect, Allied Ispat India ensures your project’s foundation is as strong as its vision.

Frequently Asked Questions (FAQs)

1. What makes Allied Ispat India’s POP parts moisture-proof?

All POP frames are made from galvanized steel with a protective coating, ensuring superior corrosion resistance and long-term durability even in humid or coastal environments.

2. Can I order customized POP frame lengths for my project?

Yes. Allied Ispat India offers customizable lengths (8ft, 12ft, or specific dimensions) to suit your design and reduce installation wastage.

3. What is the minimum order quantity for bulk buyers?

MOQ varies based on product type and customization needs. For OEM and large-scale orders, the Allied team provides flexible bulk pricing and packaging options.

4. How quickly can orders be fulfilled?

Standard items are usually ready for dispatch within 5–7 working days, while customized or export orders take 10–14 working days depending on specifications.

5. Does Allied Ispat India export POP parts internationally?

Yes, Allied Ispat India serves global clients with export-grade packaging and documentation support for seamless international trade.

Conclusion: Build Smarter, Build Stronger with Allied Ispat India

In the world of architecture and interiors, details make the difference and Allied Ispat India ensures that every ceiling section, every frame, and every structure reflects quality, durability, and design excellence.

By combining ISO 9001-certified precision, moisture-proof GI engineering, and B2B manufacturing solutions, the company continues to set new benchmarks in India’s construction and interior industry.

If you’re a designer, builder, or contractor looking for a POP parts supplier in India that values craftsmanship as much as you do, Allied Ispat India is your trusted partner.

Allied Ispat India — Head Office

69, Chotta Sonapur, Maulana Shaukat Ali Road, Mumbai — 400008

Phone: +91 98211 77009

Manufacturing Works

Plot No. C-17/9, MIDC Taloja, Behind Bank of Baroda, Dist. Raigad 410208

Phone: +91 87790 51606

Email: info@alliedispatindia.com | sales@alliedispatindia.com

Website: www.alliedispatindia.com

Direction: https://maps.app.goo.gl/iNK8ZZvn85h5absd6

Allied Ispat India – Strength. Precision. Perfection in Every Frame.